Enigma Saintia Solusindo, PT

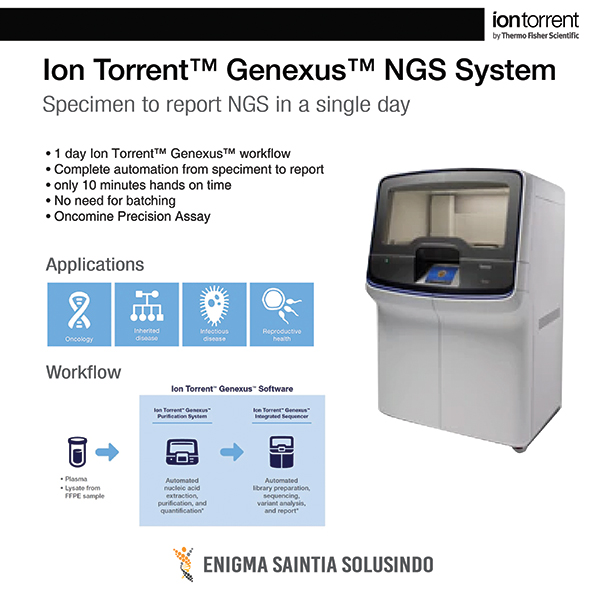

SPECIMEN TO REPORT IN A SINGLE DAY WITH A HANDS-OFF, AUTOMATED WORKFLOW The Ion Torrent Genexus System is the first turnkey next-generation sequencing (NGS) solution that automates the specimen-to-report workflow and delivers results in a single day with just two user touchpoints. This highly flexible system lets you process samples—even just one—cost-effectively as they come in. And its simplicity and practicality make it easy for your clinical research or testing lab to bring NGS in-house, regardless of your team’s current level of NGS expertise.

Showa Denko Singapore Pte Ltd

LC/MS/MS ANALYSIS OF GLYPHOSATE AND GLUFOSINATE (VT-50 2D) Organophosphate herbicides such as glyphosate and glufosinate are globally used in non-selective weed killer, effective for most weeds. Most countries set regulations for organophosphate herbicides use due to concerns on their toxicity. Therefore, monitoring their concentrations in environment and foods are required. Those compounds are highly hydrophilic, thus HPLC is a preferred analysis method. However, they are hardly retained under reversed phase mode. As a result, methods using pre-column derivatization or addition of ion-pair reagent to the eluent are often used. In this application, HILICpak VT-50 2D, a polymer-based HILIC mode column, was used under alkaline conditions. The results demonstrated the method’s feasibility for the simultaneous LC/MS/MS analysis of glyphosate,

glyfosinate, and their metabolites, as well as ethephon, a plant growth regulator which has similar structure to glyphosate. The method proved to provide 1 ng/mL level quantification of the compounds. The method developed here provides a simple and highly sensitive analysis without the use of derivatization nor use of ion-pair reagent. The pH of the eluent used was about 9, thus the system needs to be alkaline tolerant. The use of alkaline eluent improves the peak shape (less tailing) of glyphosate than using an acidic condition. Note that these phosphorus containing pesticides have tendencies of forming metal coordination compounds, therefore select PEEK materials for the flow-line after the injector wherever it’s possible.